Have you ever noticed that your flashlight gets warm after using it for a while?

Some people might think that the heat emitted from the flashlight during usage indicates a quality issue, as excessive heat could imply malfunction, discomfort when held, and even a risk of circuit short-circuiting or fire.

Conversely, others believe that a warmer flashlight indicates efficient heat transfer from the LED to the casing. So, which of these opposing views is correct?

My answer is that, in reality, both perspectives have some validity, but they’re not entirely accurate. Just because the flashlight’s outer part gets hot doesn’t always mean it’s good at getting rid of heat. And conversely, a cooler casing doesn’t necessarily mean poor heat dissipation.

Why is that? As someone with over two decades of experience in flashlight production and design, I’d like to share my insights to help you make informed choices when selecting a flashlight that suits your needs.

Why does a flashlight generate heat when it’s in operation?

LED efficiency

First, let’s understand why a flashlight’s casing heats up during use. The reasons are as follows:

The primary reason is that the operation of an LED flashlight involves converting electrical energy from the battery through a circuit to the LED, which then transforms the energy into light. However, current technology hasn’t yet achieved 100% efficiency in converting electrical energy into light; it’s typically below 50%. This means that only a small portion of the energy is converted into light, while the majority is converted into heat. This is why we often say, “Where there’s light, there’s heat.” Similar to a household light bulb, which also emits heat during use.

Voltage regulation

Flashlights often use voltage regulation to maintain consistent light output, especially as the battery voltage drops during use. The voltage regulation circuit generates heat while adjusting the LED current.

Battery efficiency

Batteries play a crucial role in powering flashlights, but they also have limitations in energy conversion. When the flashlight draws power from the battery, some energy is lost as heat within the battery itself.

The heat from electronic components

Flashlights may contain various electronic components like circuit boards and resistors to control light output or enable different modes. These electronic devices also generate heat while in operation.

Compact design

Many flashlights are designed to be compact and portable, which limits their surface area for heat dissipation. Inadequate heat dissipation mechanisms can lead to temperature rise.

High-power modes

Some flashlights offer high-power or turbo modes to increase brightness. While these modes are useful, they also generate more heat due to higher energy demands.

Hazards of Excessive Temperature in Flashlights During Operation

With flashlights getting really hot, what dangers can too much heat cause?

Overheating poses several risks to flashlights:

Performance degradation

Excessive heat can lead to performance deterioration. Overheating can cause LEDs to degrade faster, leading to yellowing of the light, reduced output, or even failure over time.

Reduced lifespan

Components subjected to high temperatures may wear out faster, shortening the flashlight’s lifespan. Battery capacity and overall lifespan can also be adversely affected by overheating.

Battery damage

Heat negatively affects the chemical composition of batteries, potentially reducing their efficiency and capacity. This can lead to faster battery depletion and more frequent replacements.

Safety concerns

Overheating poses safety hazards, particularly if heat isn’t dissipated properly. Overheated batteries might leak, vent gas, or even rupture, posing risks of chemical exposure or fire.

Structural damage

Prolonged exposure to high temperatures weakens the integrity of the flashlight’s casing and internal components. This may lead to physical damage, affecting the flashlight’s overall functionality and durability.

User discomfort

A hot flashlight can be uncomfortable or even unsafe to hold for extended periods, limiting its practical use.

Increased energy consumption

Heat generation often accompanies increased energy consumption, as more electrical energy is converted into heat rather than light. This can lead to shorter battery life and more frequent replacements.

Reduced operational efficiency

Accumulated heat within the flashlight can hamper heat dissipation and result in decreased energy conversion and light-emitting efficiency. Such inefficiency may further contribute to heat buildup and potential performance issues.

To mitigate these risks, high-quality flashlights must be designed with effective heat dissipation mechanisms, such as heat sinks and proper ventilation, to efficiently manage and dissipate heat.

How to Keep the Flashlight Cool

Given that heat is inevitable and excessive temperatures can harm flashlights, designing a flawless heat dissipation system is crucial. How can we enhance a flashlight’s heat dissipation efficiency?

Material Selection and Physical Design

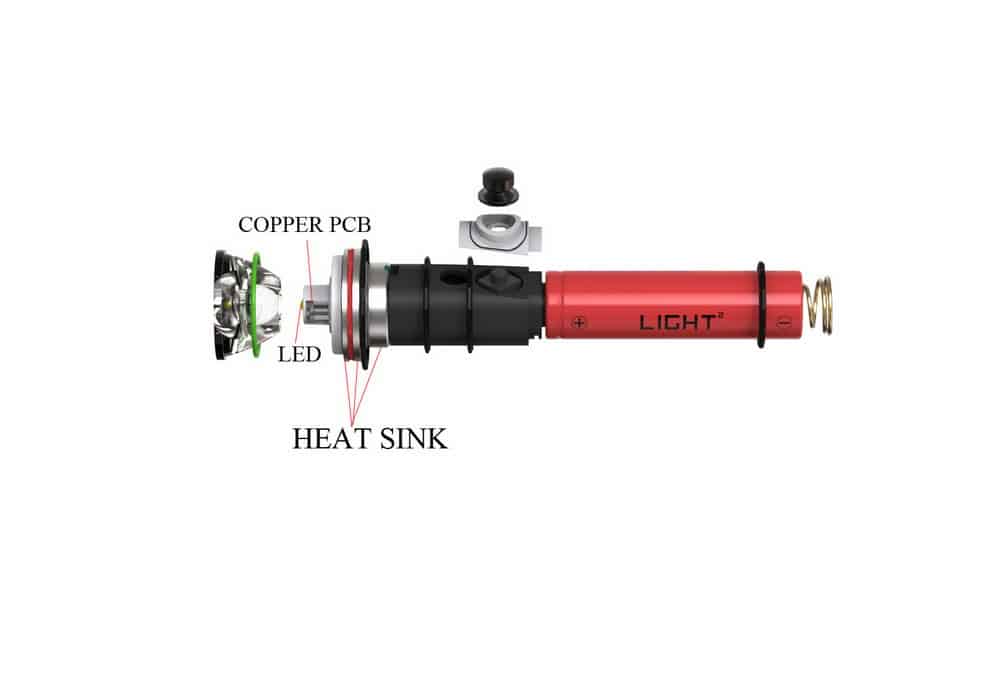

Circuit Board: As mentioned earlier, the primary source of heat in flashlights is the LED chip. Quick heat transfer from the LED is crucial, and the circuit board material is of paramount importance. Opt for materials with a higher specific heat capacity. Copper and aluminum are common options, with copper having better heat conductivity.

Heat Sink

A heat sink connects the circuit board to the LED, aiding in transferring heat to the casing. Larger heat sink surfaces result in better heat dissipation and are often designed as fin-like structures.

Casing: Flashlight casings can be made from various materials like aluminum alloy, stainless steel, or plastic. Aluminum alloy strikes a balance between heat dissipation, weight, and cost, making it suitable for flashlight casings.

Casing Material

In summary, flashlight heat dissipation involves transferring heat from the LED to the circuit board, then to the heat sink, and finally to the casing, which dissipates heat into the surrounding air.

Circuit Design

Brightness Regulation: Different flashlight modes generate varying amounts of heat, with higher brightness modes producing more heat. To ensure longevity, flashlight circuitry can be designed to gradually reduce voltage and heat emission as the temperature rises during extended high-brightness operation.

Generally, as an experienced manufacturer, we aim to keep the flashlight casing temperature below 50 degrees Celsius to prevent discomfort and potential burns for users.

In conclusion

The viewpoints presented at the beginning of this article can be synthesized as follows:

- The flashlight casing getting warm during use is normal as long as the temperature remains within an acceptable range (e.g., around 50 degrees Celsius), indicating no quality issues.

- A warmer casing doesn’t necessarily equate to better heat dissipation. Heat transfer within flashlights involves multiple channels, and a cooler casing doesn’t necessarily indicate poor heat dissipation. In some cases, inadequate heat dissipation might be due to subpar internal design or material choices, leading to LED overheating. Such flashlights should be considered of lower quality.

In summary, effective heat dissipation is crucial for flashlights. While a flashlight can function without ideal heat dissipation, enhancing heat dissipation is essential for extending its lifespan.

To gauge flashlight quality, it’s vital to consider both external and internal design aspects. Opting for experienced and professional manufacturers like us might be slightly more expensive, but it guarantees reliable quality, helps you avoid potential pitfalls, and saves time in supplier selection.