Nowadays, headlamps are becoming increasingly popular because they allow people to free their hands and do more important things while illuminating their surroundings. Modern headlamps are becoming lighter, more comfortable, brighter, and have longer illumination times.

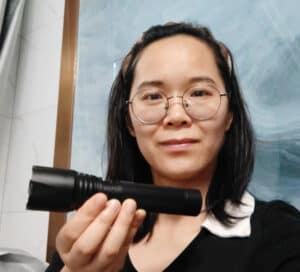

But do you know how many components are included in a headlamp? Do you know what processes are involved in assembling a headlamp? Please read the following text and images for instructions.

Section 1: Install the negative and positive spring sheets

1. Install the negative and positive spring sheets into the two card slots on the upper right side of the battery box (as shown in Figure).

2. Install the positive and negative spring sheets into the two card slots on the lower left side of the battery box (as shown in Figure).

3. The positive terminal spring is inserted into the slot marked with a positive sign on the upper right side of the battery box from the backside. (see Figure)

4. The negative terminal spring is inserted into the slot marked with a negative sign on the lower left side of the battery box from the back side (see Figure). Complete the next step of the process.

Section 2: Solder LED in circuit board

1. Separate the assembled circuit board into individual pieces (as shown in Figures).

2. Insert the positive and negative poles of the two Φ5 red light-emitting diodes (LEDs) into the corresponding slots on the control circuit board (as shown in Figure).

3. Use a soldering iron to solder the two LEDs firmly in place (as shown in Figures ). Proceed to the next step.

Section 3: Install “O” – ring and heat sink

1. Put the two 3×0.75″ “O”-shaped rings (transparent) on the Φ5 red LEDs (as shown in Figures).

2. Attach the heat sink to the battery box (as shown in Figures).

3. Align the switch on the control board with the hole on the battery box, and insert the pins of the positive and negative spring sheets into the two solder pad holes (as shown in Figure). Proceed to the next step.

Section 4: Install spring sheets

Use a soldering iron to solder the positive and negative spring sheets firmly in place (as shown in Figures ). Proceed to the next step.

Section 5: Install wires for LED

1.Solder a Φ0.8x15mm red silicone wire to the positive solder pad of the LED, and a Φ0.8x15mm black silicone wire to the negative solder pad (as shown in Figures).

2. Use pliers to split the LED from the edge of the copper substrate (as shown in Figure). Proceed to the next step.

Section 6: Connect the LED wires to the circuit board

1. Bend the two wires on the LED along the edge of the LED (as shown in Figure ).

2. Solder the red wire to the positive solder pad on the control board (as shown in Figure ).

3. Solder the black wire to the negative solder pad on the control board (as shown in Figure ). Proceed to the next step.

Section 7: Install LED cover

1. Apply a suitable amount of thermal conductive silicone grease to the top of the LED heatsink and press the LED tightly onto the top of the heatsink. (See Figures)

2. Align the LED cover with the LED installation. (See Figures)

3. Use a plum-shaped hexagonal self-tapping screw to drill two holes in the middle of the back of the battery box, and lock the LED cover firmly in place. (See Figures) Complete and move on to the next process.

4. Use a dust-free cloth to wipe the surface of the LED clean. (See Figures )

Section 8: Add logo around the LED

1. Use a dust-free cloth to wipe the surface of the LED clean.

2. Paste the LED cover adhesive on the LED cover.

3. Apply (TUB814-L2) lubricating oil to the focusing slots on both sides below the cover. Complete and move on to the next process.

Section 9: Fit the “O” – ring onto the headlamp cover

1. Fit an Φ18X1.5 “O” ring (red) onto the front cover slot. (See Figure)

2. Install the front cover waterproof sleeve inside the front cover. (See Figure)

3. Apply a circle of (TUB814-L2) lubricating oil to the “O” ring position on the front cover. (See Figure)

4. Screw the front cover into the headlight housing. (See Figures ) Complete and move on to the next process.

Section 10: Install the lens

1. Wipe the lens of the qualified product clean and install it into the front cover. (See Figures)

2. Align the two notches on the front cover with the positioning points on the fixture, and press it into the punching fixture. Install the lens pressure ring on the punching fixture, and then punch it into place. (See Figures)

3. Use an air gun to blow the lens clean. (See Figure) Complete and move on to the next process.

Section 11: Install the battery box assembly into the headlight housing

1. Use an air gun to blow the front cover and LED clean. (See Figures)

2. Install the socket plug into the housing slot. (See Figure)

3. Install the battery box assembly into the headlight housing, press it with one hand, and then twist the front cover clockwise to fit it into the LED cover slot. (See Figures)

4. Install three plum-shaped hexagonal self-tapping screws in the screw holes and tighten them with an electric screwdriver. (See Figure) Complete and move on to the next process.

Section 12: Install the battery cartridge cover

1. Install one side of the flat surface of the headlamp waterproof gasket B into the headlight back cover. (See Figure)

2. Install the headlamp base plate into the headlamp back cover. (See Figure)

3. Install the back cover into the housing. (First, install the end without the notch, and then fit the other end into place along the notch). Complete and move on to the next process (See Figures).

Section 13: Install the battery pack

1. Install the rechargeable battery pack and press the headlamp 2PCS switch to test the function (as shown in Figure 1, Figure).

2. Turn on the headlamp to check the spotlight and floodlight effects. There should be no shadows, slanting, over-diffusion, or over-concentration (as shown in Figures).

3. Plug in the charger to test the charging function.

Section 14: Check is everything installed correctly

1. Check the appearance of the finished product. There should be no scratches, air bubbles, or other defects.

2. Check the focus of the front cover. It should not be too tight, too loose, or stuck.

Section 15: Headlamp charging and discharging test

1. Take the headlamp to the charging rack for 3 charge and discharge tests (as shown in Figure ).

Now, the assembly work of one headlamp has been completed. The next job is to take the headlamp to the charging rack for 3 charge and discharge tests, install the stripe, and then packaging, then it ready for shipment.

Conclusion

The assembly of the headlamp appears to be a daunting task as it consists of thirty to forty components and looks extremely complicated. However, assembly is actually the easiest task of all our work because we break it down into multiple sections and then further divide each section into many small installation steps. After providing adequate training to employees and establishing SOPs (Standard Operating Procedure), the task can be completed quickly, efficiently, and accurately.