The light beam is crucial when choosing a suitable flashlight for a specific task. The flashlight’s secondary optics system plays a vital role in shaping and directing the beam of light produced by the flashlight. But different optics systems work in different ways and have their own unique set of features and benefits. Do you know how to choose the right secondary optical system for your light?

Why need secondary optics system?

LED chip is the primary optical system. LED chip has the following characteristics:

The angle is mostly 120° (of course, there are other angles such as 80° or 150°), so the light intensity is relatively low. The LED light dazzles people as it is scattered everywhere and is not easy to control. While usually, the flashlight uses a narrow range of light, so it needs a secondary optics system to reduce the angle of the LED chip.

What’s a secondary optics system?

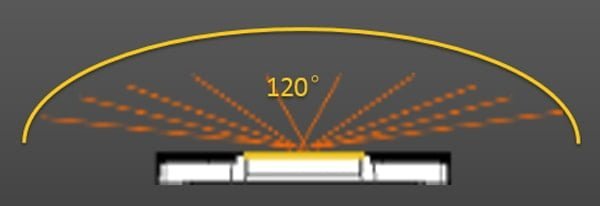

A secondary optics system in a LED flashlight refers to an additional lens or reflector placed in front of the LED to shape and direct the light beam. People use the optics system to focus or spread the light beam, providing a more targeted or wider illumination area. The flashlight’s secondary optics system usually refers to a lens or reflector.

Lens

A lens is a transparent and transmissive optical device that focuses or disperses a light beam by means of refraction.

Reflector

A reflector is a non-transparent plastic or metal optical device that reflects light in a required direction.

What are the uses of secondary optics systems?

Secondary optics has the following characteristics:

Use various devices such as lenses & reflectors to achieve the required light angle and controls the light direction. It also reduces glare and pollution and provides a comfortable and healthy lighting environment. Improve the effective utilization of light and bright light art to life.

Difference between lens and reflector.

The lens is a transparent material that beams can through it, while the reflector is lightproof material. The above image shows that each light refracts through the lens and is under control. But a part of the beam from the reflector is straight up without processing.

From the perspective of light intensity, when the light source comes from the same angle, the lens has better light control, so its light intensity will be 10%-20% higher than the reflector. Furthermore, focusable flashlights are equipped with a lens. The reflector is for no focusable flashlight only.

Materials for the lens.

The common materials of the lens are PMMA (polymethyl methacrylate), PC (Polycarbonate ), tempered glass, and silicone.

PMMA (polymethyl methacrylate)

PMMA is the most common lens material, with good plasticity, high light transmittance (up to 93%), stronger UV resistance, and no yellowing after long-term use. The beam through the PMMA lens is relatively uniform.

The disadvantage of PMMA is the heat resistance is lower than PC, only about 70 degrees. But its self-absorption of heat is relatively low, so the heat resistance of PMMA is not much lower than PC in terms of temperature resistance.

PC (Polycarbonate )

PC is a high-temperature resistance (above 130°C) optical material.

The disadvantage of the PC lens is that the light transmittance is slightly lower (87%).

Tempered glass

Tempered glass is a high-quality material with high light transmittance (above 97%) and high-temperature resistance. For example, the LEP (Laser Excited Phosphor) flashlights use tempered glass lenses.

The disadvantage of the tempered glass lens is that it is fragile, difficult to process, and expensive.

Silicone

The heat resistance of silicone can be up to 200°. Silicone anti-UV ability is better than PMMA. It has strong flexibility. The silicone lens is self-sealing, and the waterproof and dustproof level reaches IP67. The silicone lens is lighter and achieves more precise optical angles than glass.

The cost of silicone lenses is too high, so it’s not a popular optics material in the market till now.

Materials for the reflector.

The regular materials of the lens are PC and aluminum alloy.

PC (Polycarbonate )

The reflector made by PC injection molding has high optical surface precision and good consistency. And the cost of a PC reflector is much lower than the same dimension aluminum alloy reflector.

But a PC reflector is unsuitable for super high-temperature lights as its heat resistance is 130℃.

Aluminum alloy

Aluminum alloy reflector has good heat resistance. It’s suitable for high-temperature lights.

The cost of making an aluminum alloy reflector is extremely high. Making an aluminum alloy reflector includes stamping, polishing, and internal surface coating processes. It costs more than twice the price of a PC reflector but has a less accurate optical surface than a PC reflector.

At last , please note no matter what kind of material the reflector is, its LED is exposed. So, all reflectors need a cover to seal them to get waterproof, and dustproof and prolong the LED service life.

Classification of the lens.

There are many more types of lenses than reflectors.

TIR lens

TIR is short for total internal reflection. The design principle of the TIR lens is to use penetrating light gathering in the center of the lens. At the same time, the conical surface can collect and refract all the side lights. And the overlap of these two kinds of light can get t uniform and concentrated light beam.

The efficiency of the TIR lens can reach more than 93%. It is mainly used in small-angle lights (beam angle <60°).

TIR is a fixed-focus lens, so it’s not suitable for focus-adjustable flashlights.

Focus adjustable lens

Focusing adjustable lenses are used in focusing adjustable flashlights. The beam is focused in focus mode with no flood light around it. The beam in flood is a large flood without a central light. There are two focus adjustable lenses: plano-convex lens and composite lens.

Plano-convex lens

A plano-convex lens has a convex spherical surface on one side and a flat one on the other. It is the most basic focus adjustable system.

Features of this lens are as below:

When a plano-convex lens is in focus, its spot beam is not round, but the shape of the LED itself is revealed.

To avoid this situation and get a nice round spot beam, we can design the flashlight structure to control the flashlight in a position where it cannot get to the most focused place so that the spot beam is bigger. It means the beam intensity gets lower, and the beam distance is shorter.

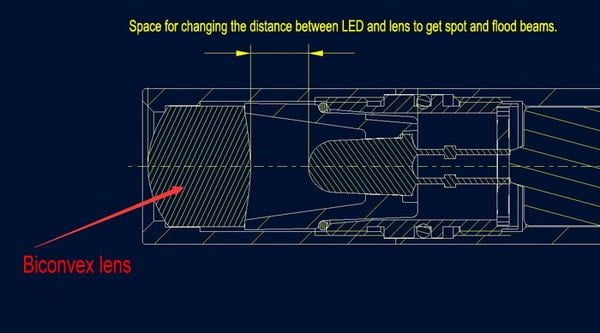

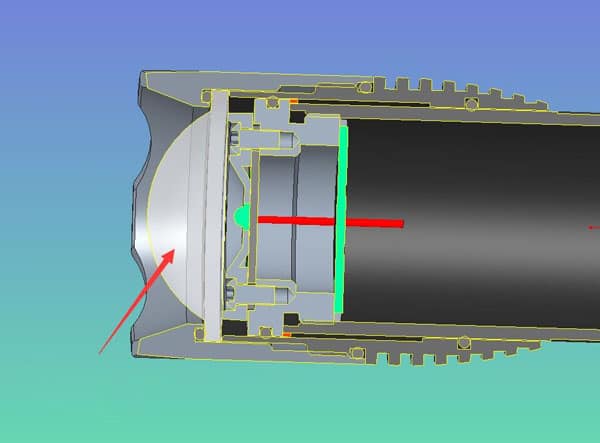

Composite lens

The composite lens is the biconvex lens and TIR lens in one, or the biconvex lens and reflector in one. There is a sunk bottom under the composite lens for the LED chip to move into the lens sunk when sliding the flashlight to get a spot and flood beam.

Classification of the reflector.

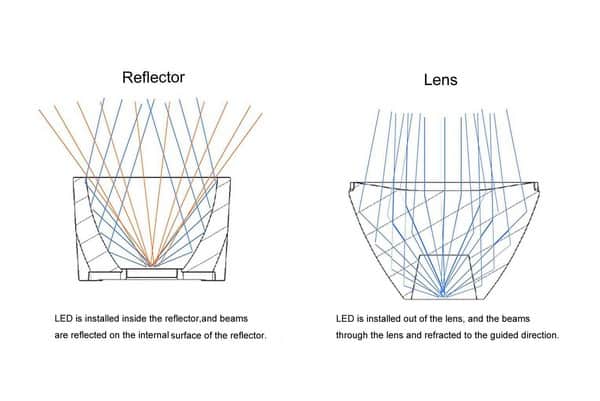

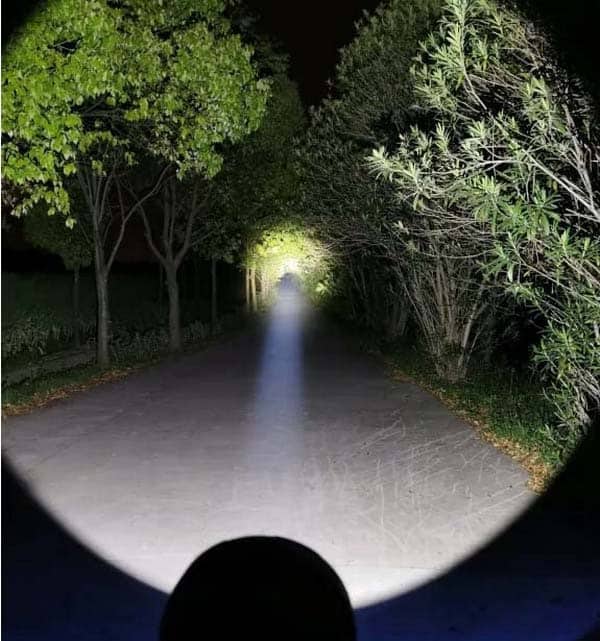

The reflector is simpler than the lens. The beams from the reflector are as below:

From the image, we can figure out there is a strengthened beam in the middle, and there is a large area of floodlight around the beam, so that the field of vision is relatively wide, which is in line with human vision habits, that is, there is scope and focus.

The reflector diameter, depth ratio, and reflective curve affect the beam pattern and distance. The larger and deeper the reflector, the brighter the spot beam, and the longer the beam distance you get. So to get a long-distance shooting, you need a relatively large flashlight head to achieve.

According to the internal surface treatment, the reflector is divided into mirror-treated, orange peel, and micro orange peel reflectors.

Mirror-treated reflector

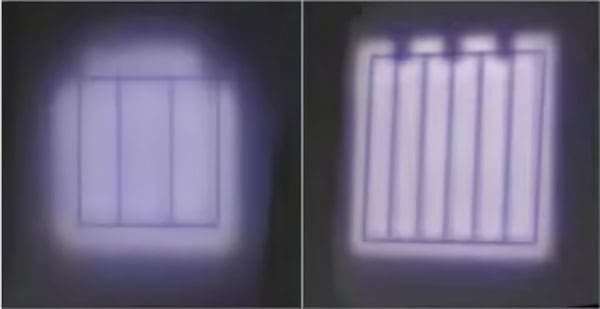

The mirror-treated reflector (glossy cup) has higher reflection efficiency, the center spot is brighter, and the brightness of the flood area is low. The beam from mirror treated reflector is dizzy.

The mirror-treated reflector allows you to get the brightest and longest beam if the LED chip is appropriately placed.

However, if the LED is placed too far out or too far back, a black ring will appear in the beam central.

Orange peel reflector

The orange peel surface reflector has an internal surface that appears to be made up of tiny bumps (commonly known as orange peel).

The orange peel surface reflects the light evenly after the light is reflected many times in the uneven reflective cup. Hence, the central spot is not as prominent as the mirror reflective cup, and the spot beam is beautiful.

The characteristics of the beam from the orange peel reflector are uniform and anti-dizzy.

Micro Orange peel reflector

The micro orange peel reflector is between the mirror surface and the orange peel, which cleverly solves the excessive concentration of the mirror reflector and the excessive floodlight of the orange peel reflector.

How to choose the right secondary optics system for your flashlight?

Knowing each secondary optics type’s features and materials helps you choose the appropriate optical system for your flashlight.

Determine your needs

The first thing to determine is the use scenario of the flashlight. Is the beam focusable, uniform, or long-distance? You can select a suitable lens or reflector based on the above information.

Consider the size

First of all, consider the battery size before choosing secondary optics system. And then, choose the matched size of the lens or reflector. Is the size of the flashlight head bigger than its body, or is it the same size? Then you can determine a diameter for the lens or reflector.

Check the material

The material of the lens can also impact the performance of the flashlight. And it also affects the cost. Generally speaking, PMMA is the best material option for a lens with good characteristics and affordable prices. And PC is suitable for most flashlight reflectors. An aluminum reflector is good, but it costs a lot.

I believe that after reading this article, you will be able to choose a right lenses or reflector for your project. That’s all for this topic. Thanks for reading. Welcome to contact me.