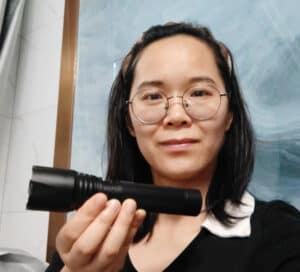

As a portable outdoor lighting tool, a flashlight allows us to explore the dark world. A good quality flashlight will keep you from getting lost in the dark. While a poor-quality flashlight will bring you an experience that is more terrible than the night. But how do I know if is it a good-quality flashlight? And how to inspect it?

What are the qualities of a good flashlight? You must have known many flashlight brands including LEDLENSER, FENIX, COAST, OLIGHT, STREAMLIGHT, NITECORE, THRUNITE, NEXTORCH, SUPERFIRE, MAGLITE, and more. And there are also so many LED flashlight suppliers on Alibaba. Most of the brands’ flashlights are of good quality, but the prices are super high. In comparison, some suppliers offer flashlights at unbelievably low prices. Quality and price are always contradictory. So how can we select a flashlight with durable, stable quality but at an acceptable price?

To find a good flashlight, we first need to know what kind of flashlight is a good flashlight. I created this blog with my ten years of flashlight manufacturing experience. After reading this article, you will become a flashlight expert. Here we go!

Flashlight surface

The first step in checking your flashlight is to see how it looks.

The flashlight surface shall be free of damage, scratch, stain, rust, oil spray, and other defects that affect the appearance. The colour should be uniform and without a colour difference. And then, Take a closer look at below points:

- Whether the installation of each component is firm and reliable, without looseness or deformation, the connection flashlight head, body, and rear cap should be gap-free, with no cracks, dislocation, distortion, or damage. The edges and corners of the flashlight should be smooth and not sharp.

- The lens or optics of the flashlight should be clear and free of any minor tiny damage.

- The circuit contacts, spring, and stainless-steel (or golden-plated) fittings, such as screws and nuts, should be bright and rust-free, with no deformation, looseness, or damage.

- The battery shall be clean and dry, free of leakage and expansion.

Material

Inferior materials can’t create a good product. A good flashlight must be made of suitable materials. Please check below critical materials for a flashlight:

- Casing: There are generally three kinds of flashlight casing, aluminium alloy, stainless steel, and plastic. Compared with the three materials, the stainless-steel flashlight is the most durable material. But stainless-steel material cost and machining costs are expensive; Plastic is not a good material for flashlight casing, as it doesn’t dissipate heat well; Aluminium alloy is a perfect material for flashlight housing as it is reasonable material cost and easy to machine. Furthermore, it’s good for heat dissipation and is lightweight and easy to carry. Therefore, 90% of flashlights are made of aluminium alloy. Caution: If your aluminium alloy flashlight casing has impurities and is lower than the market price, it’s probably made of recycled material.

- LED: The top three brands of LEDs are CREE, OSRAM, and LUMINUS. Most of the flashlight brands on the market use these three brands of LEDs. We have been making flashlights with Cree LEDs for more than 20 years, and we have basically not encountered problems caused by the LEDs themselves. I have to say the quality of Cree LED is really stable.

- Battery: Rechargeable batteries power most flashlights. It is very important for rechargeable batteries to have overcharge and over-discharge protection. Because both overcharged and over-discharged are harmful to the battery and its life span. What’s more serious is over-charged will also make the rechargeable lithium battery too hot to burst or catch fire. But each battery with overcharge and over-discharge protection costs about $0.5 more. 95% of the cheap batteries on the market do not have the over-charged and over-discharged protection function. Buying these flashlights without battery over-charged protection is to bury the seeds of a potential safety hazard around you.

- Surface treatment: A good quality surface treatment should be bright and uniform in colour and not easily scratched. Some cheap flashlights look dull on the surface. The surface colour has not fully covered the colour of the material itself.

- Weight: A good quality flashlight’s weight is heavy-duty because its material is relatively thick. But the same size is cheap the flashlight is much lighter to hold.

- Accessory: If it’s rechargeable, a flashlight should at least sell with a charger, cable, battery, and operating instructions. Some good quality flashlights also come with a holster and lanyard. Some cheap flashlights don’t have a charger, and the cable is only 15 cm in length, but regularly it should be 100 cm. The cable shall be free of broken skin and exposed copper.

Structure

Whether the system of the flashlight is firm or not directly determines whether it is durable. When you check the structure, you need to look at the following points:

- Radiator: When the LED is working, it generates heat. Too much heat will cause LED ageing and colour change, and even too high a temperature will burn the LED. A good radiator is needed to help dissipate heat. Those cheap flashlights don’t have a radiator, so they can easily burn out the LEDs when they’re in use.

- Circuit board soldering: The LED is soldered to a copper or aluminium substrate. Whether the welding is firm or not is very important. If it’s poor soldering, the circuit will be blocked, and the light will not work. To find out if a flashlight is poor soldering, we need to give the flashlight some impact, such drop test. So, you need to prepare extra one or two flashlights for the test. Noted: the drop test can damage your flashlight. If you don’t have an extra flashlight to drop the test with, you should at least do this:

- Place the flashlight on a horizontal surface, shake it vigorously, and pay attention to the fact that there is no abnormal noise inside the product.

- Please turn on the flashlight and put it close to your ear. If you hear a squeak, the noise is too loud, and the circuit board needs to be modified.

- Screw thread: the screw wall on the flashlight casing is the most fragile as it is thin after the screw is machined. Press your hand hard on the screw wall to see if it will crush it.

- Switch: Whether the switch button of the flashlight bounces back fast and strongly after being pressed. Some poor-quality flashlight switch buttons are bounced back weakly because the spring under the switch button is not long and thick enough. A good switch should be able to be pressed more than 20000 times. To see if it is a good switch, manually switch the on and off more than 500 times, and the flashlight works correctly without any abnormality.

- Charging port: whether the charging port is protected well. Is the silicone or other material of the charging port firm? If the cover of the charging port is easy to fall off, it will affect the flashlight’s waterproof and dustproof functions. Insufficient protection of the charging port will shorten the service life of the flashlight.

- Pouch/lanyard/clip: If the flashlight comes with a pouch, lanyard or clip, it is necessary to check whether the pouch can hold and fix the flashlight from moving. Or if the lanyard/clip is firmly connected to the flashlight. Poor protection will drop out your flashlight.

OPerating

Flashlight is a lighting tool. Tools shouldn’t make things more complicated. So a flashlight should be simple and easy to use. It should be easy to turn on, and off as expected. And you can get any mode of light you want easily, such as a low beam. In addition, when the flashlight is placed in your backpack, it should not be easy to switch on automatically.

Light beam effect

After the power switch is turned on, there should be no flicker or spots outside the beam area. The flashlight light should be a uniform beam, and the spot should be in the centre of the beam. With the increasing power of flashlights, the size of LEDs is also increasing, so the range of its light spot is also increasing. The higher the power of the LED, the larger beam you get.

Charging

- Is there a charge indicator? In this way, when you charge it, you can know is it in charging as expected and when it is fully charged.

- Does the charger have over-charged protection? If there is no overcharge protection, the charger will not stop working after the flashlight is fully charged, which will lead to high temperatures and might cause a fire.

- The USB-C charging port is easy to use and more durable than Micro USB. So, the Micro USB is replaced step by step now. If you have no idea about USB-C, please check USB-C type in Wikipedia.

- The flashlight should be able to be charged and discharged more than 500 times.

- Generally speaking, fully charging a flashlight should be done within 4 hours.

- A 20-120W PD charger allows you to get a shorter charging time.

Technical data

The data of many brands of flashlights on the market are falsely marked. The actual value of data is only 70% or less of its marks. You’d better choose the manufacturer who follows up with ANSI standards. For more details, please check my previous post: Things You Need to Know about ANSI / NEMA FL1-2009.

Packaging

Flashlights are easy to scratch, and each flashlight should be separately packaged with protective packaging to prevent them from colliding.

Conclusion

After a long time of using and repairing the flashlight, we found that its impact-resistant and waterproof functions affect the flashlight’s service life. That is to say, with the exclusion of material problem, most of the flashlight’s quality problems are caused by impact and water. So when you’re inspecting a flashlight, pay attention to its impact-resistance and water resistance. That’s all for this topic, thanks for reading!